Wire bonding is a primary procedure inside the electronics manufacturing panorama, enjoying an crucial position in connecting countless system within semiconductors, medical gadgets, and past. The cord bonding task ensures that electrical connections are made reliably and efficiently. In this text, we shall delve into the countless aspects of twine bonding purposes, exploring its approaches, gear, reliability reasons, and plenty extra.

What is Wire Bonding?

Wire bonding is a way used to create electric connections among microelectronic add-ons. This technique comes to the usage of high quality wires (in many instances gold, aluminum, copper, or silver) to attach semiconductor chips to their respective substrates or leads. The task will probably be finished thru a couple of tips along with ball bonding, wedge bonding, and ribbon bonding.

How Does Wire Bonding Work?

The cord bonding activity starts off with the placement of a tiny twine on a designated bond pad on a semiconductor die. Using warm and rigidity or ultrasonic strength, the bond is shaped by means of melting the interface among the twine and the pad. After securing one stop of the wire, this is looped to one other bond pad in which it undergoes equivalent therapy.

Table 1: Common Types of Bonding Wires | Type | Material | Applications | |---------------|----------------|--------------------------------------| | Gold Wire | Au | High-frequency programs | | Aluminum Wire | Al | Cost-potent strategies | | Copper Wire | Cu | High existing applications | | Silver Wire | Ag | Specialized digital devices |

Wire Bonding Techniques: Overview

There are countless options employed in twine bonding that are selected situated on software specifications:

Ball Bonding

Ball bonding is characterized with the aid of forming a small ball on the cease of a cord ahead of creating a connection. This procedure is above all precious for prime-frequency instruments.

Wedge Bonding

In wedge bonding, the bond software makes use of a flat floor to create bonds. This methodology helps for more Have a peek here regulate over bond parameters which includes temperature and pressure.

Ribbon Bonding

This really expert approach utilizes flat ribbons of steel rather than around wires. Ribbon bonding grants diminish inductance and bigger thermal functionality.

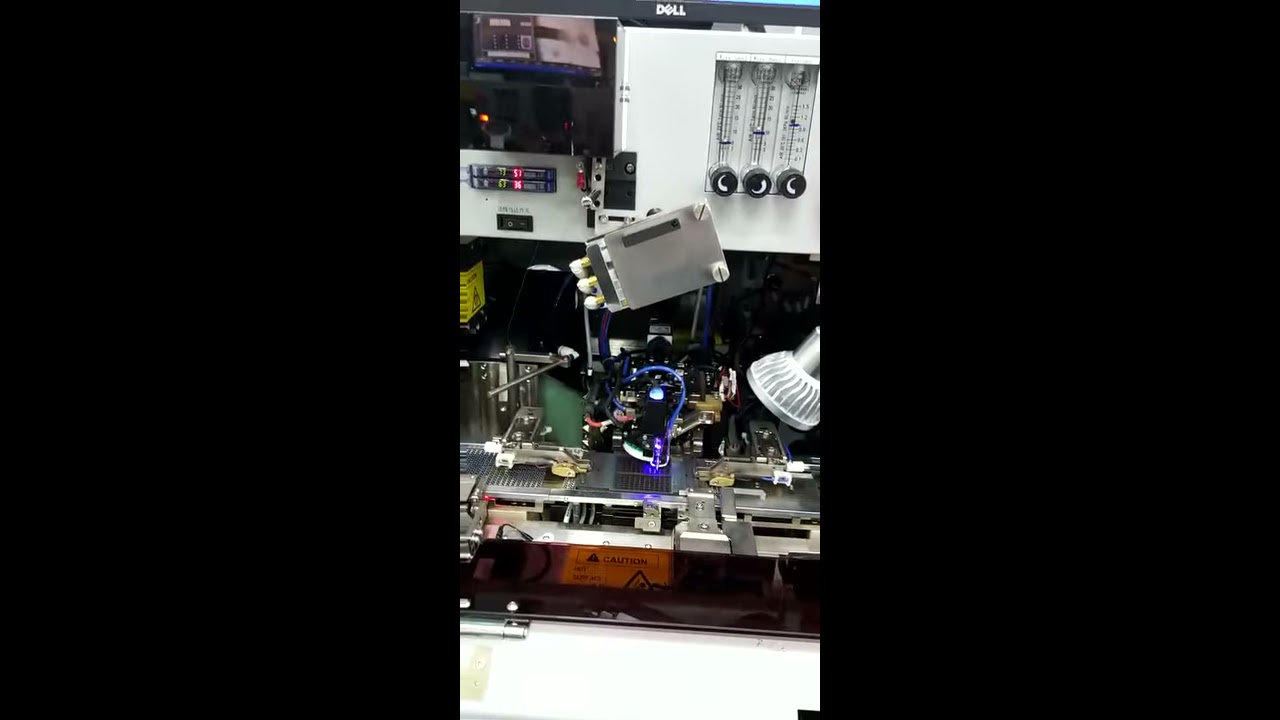

Wire Bonding Equipment: What You Need

To function wire bonding simply, distinctive machines and resources are considered necessary:

Wire Bonding Machines: These automated procedures handle many different parameters throughout the bonding procedure. Bonding Tools: Tools like capillary tubes determine detailed coping with of ultra-quality wires. Inspection Equipment: X-ray inspection techniques validate bond integrity with no unfavorable components.Wire Bonding Applications: From Semiconductors to Medical Devices

The versatility of wire bonding expertise has brought about its in style adoption throughout diverse industries:

In Semiconductors

The semiconductor enterprise closely is based on twine bonding for interconnecting included circuits (ICs). Its low fee and top reliability make it preferable for mass production.

In Medical Devices

Medical technological know-how needs utmost precision; thus cord bonding plays an quintessential role in connecting sensors and microchips used in diagnostic device.

Applications in Electronics Manufacturing

- RF modules Microcontrollers Power electronics

Understanding Wire Bonding Reliability

Reliability in twine bonding refers back to the durability and robustness of bonds under one of a kind situations. Factors influencing reliability embody:

Material Selection: Choosing compatible ingredients (e.g., gold vs aluminum) can have an impact on functionality. Bond Quality Control: Monitoring procedures by using inspection gear ensures defects are minimized. Environmental Controls: Managing humidity and temperature in the time of production maintains bond integrity.Common Failure Modes in Wire Bonding

Understanding established failures helps strengthen strategies:

- Bond Lift: A consequence of inadequate adhesion. Heel Crack: Occurs through extreme strain on junctions. Oxidation: Degradation due to publicity to air.

Cost Implications of Wire Bonding Technologies

The funding in cord bonding technology varies widely dependent on:

- Machine abilties (guide vs fully automatic). Material quotes (gold vs aluminum). Production amount requirements.

Evaluating Wire Bonding Costs

Cost assessments need to examine now not simplest preliminary investments yet also long-time period operational rates such as renovation and subject matter wastage.

Quality Control Measures in Wire Bonding

Ensuring good quality at some point of construction approaches contains numerous concepts:

Visual Inspection: Regular exams assistance determine seen defects early. Non-harmful Testing: Techniques such as X-ray can demonstrate hidden matters without compromising product integrity. Pull Tests: These exams gauge bond potential efficiently in the past final assembly levels.Training Programs for Effective Wire Bonding Execution

To grasp twine bonding strategies, complete practise techniques are important:

- Workshops that cover fingers-on adventure with device. Online publications specializing in theoretical data about material and tips.

Future Trends in Wire Bonding Technology

Emerging trends trace against options that could boost effectivity:

- Integration with Industry four.0 ideas promoting automation. Development of recent ingredients lowering bills even though keeping up overall performance degrees.

FAQs about Wire Bonding

1. What kinds of bonds are regularly used in wire bonding?

Common styles contain gold ball bonds, aluminum wedge bonds, and ribbon bonds suitable for express functions like potential modules or RF circuits.

2. How do I be certain fabulous quality manipulate throughout the time of twine bonding?

Adopt everyday inspection practices via visible exams and non-harmful checking out tools like X-ray inspection to monitor bond integrity perpetually.

3. What are a few well-known failures encountered throughout the time of the wire bonding strategy?

Common screw ups consist of bond carry-off using inadequate adhesion, heel cracks from excess tension at junctions, and oxidation from environmental exposure.

4. Is there a tremendous cost difference among gold vs aluminum cord?

Yes! Gold wires most commonly fee extra than aluminum yet supply most reliable conductivity which might justify their use based on software necessities.

5. How does environmental regulate have an effect on wire bond reliability?

Maintaining most useful humidity phases prevents oxidation at the same time controlled temperatures cut down thermal pressure all over processing stages making sure potent bonds.

6. Are there working towards classes on hand for mastering approximately progressed twine bonding recommendations?

Yes! Many establishments be offering really expert exercise methods ranging from overall tutorials to advanced workshops concentrating on ultra-modern applied sciences relating to cord bonding approaches.

Conclusion

Wire bonding stays a useful expertise across different industries ranging from semiconductors to clinical instruments as a consequence of its versatility and verified reliability over the years. Understanding its recommendations—like ball versus wedge as opposed to ribbon—and imposing superb great manipulate measures will verify victorious program influence at the same time minimizing costs linked to construction inefficiencies or mess ups down the road!

By staying advised approximately rising tendencies inside of this domain—resembling Industry 4 .0 developments—manufacturers can further refine their operations most efficient closer to even extra efficiencies moving ahead!