Introduction

In the fast-paced international of electronics production, wisdom exclusive bonding strategies is fundamental for producing secure and productive devices. One such technique that has won amazing traction in latest years is wedge bonding. This article will delve into the true-international programs of wedge bonding, exploring its merits, approaches, and varying sectors it serves. From semiconductors to scientific instruments and the whole thing in among, we’ll read how this generation is remodeling industries at the same time keeping up prime specifications in great and reliability.

What is Wedge Bonding?

Wedge bonding is a wire bonding method involving a wedge-fashioned software that creates connections between semiconductor instruments and substrates. It’s greatly utilized in many different fields because of the its ability to offer strong electrical interconnections with minimum mechanical pressure. Understanding the nuances of this method can supply insights into why it has develop into a most popular choice amongst manufacturers.

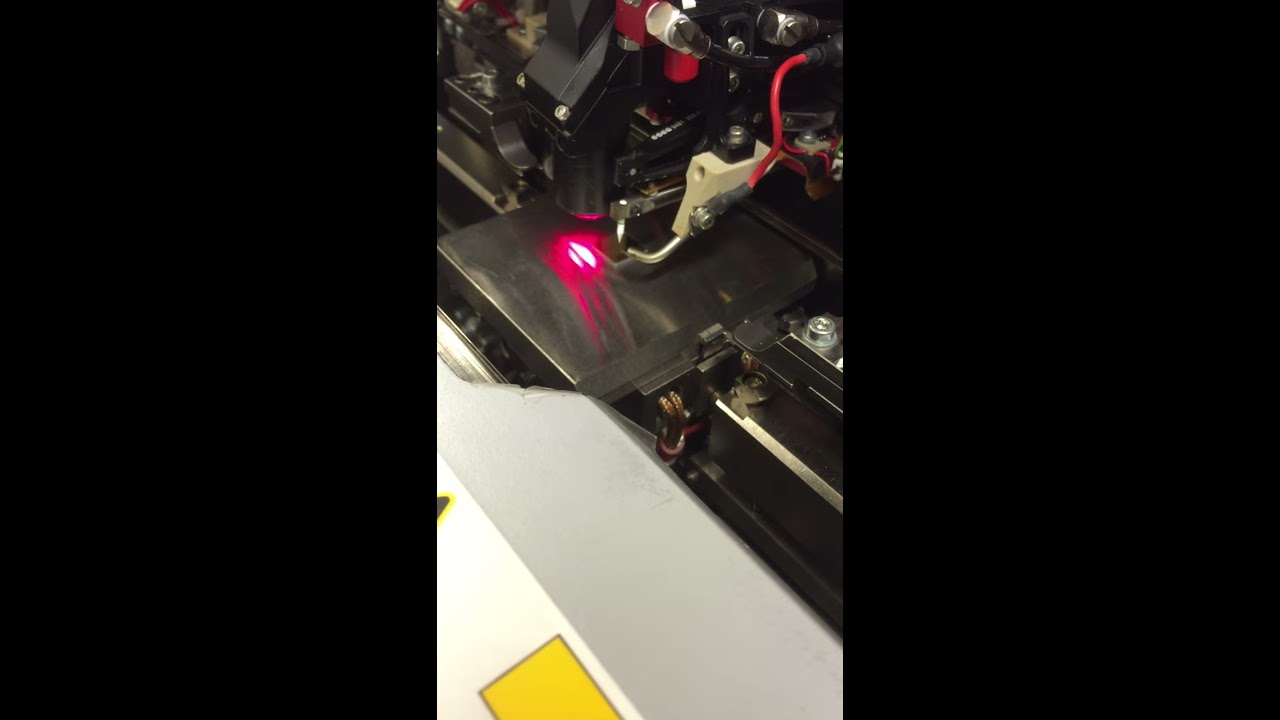

How Wedge Bonding Works

The activity starts with positioning the twine over the bonding pad at the semiconductor equipment. The wedge tool applies ultrasonic energy or warmth (based on regardless of whether it really is ultrasonic or thermosonic wedge bonding) to facilitate metal float, creating a sturdy bond. This manner lets in for high-quality management over bond parameters, contributing to high reliability.

Wedge Bonding vs. Other Bonding Techniques

When comparing wedge bonding with other systems like ball bonding or turn-chip soldering, a couple of factors come into play:

Cost Efficiency: Wedge bonding ordinarilly calls for less textile than different equipment. Thermal Stability: Wedge bonds can resist upper temperatures than some opportunities. Mechanical Strength: The bond created by means of this technique has a tendency to be extra robust lower than mechanical strain.Types of Wedge Bonding Methods

There are varied kinds of wedge bonding techniques adapted for definite packages:

1. Ultrasonic Wedge Bonding

This methodology utilizes ultrasonic strength to create bonds at shrink temperatures, making it exact for delicate constituents.

2. Thermosonic Wedge Bonding

Combining warm and ultrasonic potential, thermosonic wedge bonding complements fabric waft, ensuing in improved bonds.

3. Deep Access Wedge Bonding

Ideal for packages requiring deep entry aspects in which widespread resources would combat.

4. Insulated Wedge Bonding

Incorporates insulation around the twine for stronger defense in delicate environments.

Real-World Applications of Wedge Bonding

Now that we take into account what wedge bonding is and its different types, let’s explore its truly-world functions throughout diversified industries:

1. Semiconductor Manufacturing

Wedge bonding performs a indispensable role in semiconductor gadgets' packaging. Its skill to address exceptional pitch leads makes it the best option for cutting-edge microprocessors and memory chips.

Benefits

- High-density packaging Reduced thermal resistance Enhanced electrical performance

2. Medical Devices

In the scientific box, where reliability will probably be a depend of existence and death, wedge bonding ensures protected connections in implantable instruments which include pacemakers and sensors.

Benefits

- Biocompatibility Resistance to environmental causes (moisture, temperature) High reliability

3. Automotive Electronics

As trucks changed into progressively more reliant on electronic systems for protection and performance, wedge bonding grants sturdy answers for automobile modules equivalent to ECUs (Electronic Control Units) and sensors.

Benefits

- Enhanced vibration resistance Low-can charge manufacturing processes Improved lengthy-term reliability

four. Aerospace Applications

In aerospace expertise, in which weight financial savings are crucial with no compromising force or reliability, wedge bonding excels through cutting back the dimensions and weight of materials when maintaining functionality integrity.

Benefits

- Lightweight interconnections Resistance to severe conditions Compliance with stringent safety regulations

5. LED Manufacturing

With LEDs growing to be ubiquitous in lighting suggestions, utilizing wedge bonding improves connectivity within LED applications with the aid of imparting legit electrical contacts that face up to thermal biking tension.

Benefits

- Improved gentle output efficiency Longer lifespan of LED products Enhanced thermal administration

Wire Bonding Process Overview

To solely respect the value of wedge bonding inside its real-world programs, we have to apprehend the overall twine bonding method:

Preparation: Cleaning surfaces ensures foremost adhesion. Placement: Accurate positioning of wires by way of developed wire bonder machines. Bond Creation: Utilizing both ultrasonic or thermosonic ways elegant on program requirements. Inspection: Visual inspection followed by way of non-detrimental trying out (e.g., pull tests) ensures bond excellent. Finalization: After triumphant inspections, encapsulation or extra protective measures are implemented as essential.Challenges in Wire Bonding Reliability

Despite its diverse benefits, several challenges exist pertaining to wire bonding reliability:

Bond Failures: Common failures encompass heel cracks and bond lifting with the aid of wrong settings or infection.

Oxidation Issues: Oxidation can weaken bonds if authentic precautions aren’t taken during instruction phases.

Environmental Factors: Moisture publicity can bring about corrosion over the years; for that reason shielding coatings are in most cases encouraged.

Material Selection: Choosing between gold vs aluminum vs copper wire relies on conductivity needs as opposed to payment concerns.

FAQ Section

1. What components are primarily used in wedge bonding?

Wedge bonding more often than not uses gold and aluminum wires by using their fantastic conductivity and ductility; copper has also emerged as a cost-effective opportunity yet comes with oxidation risks that want addressing.

2. How does one verify great management throughout the time of cord bonding?

Quality keep an eye on includes diverse steps adding visual inspections put up-bond advent in addition pull exams that degree bond force opposed to preferred thresholds explained through market requirements like JEDEC.

three. Can you give an explanation for the adjustments between ball bonding and wedge bonding?

Ball bonding types a round connection through heated balls on the finish of wires at the same time as wedge bonds use flat surfaces pressed in combination; every has uncommon merits relying on software necessities like pitch dimension or environmental conditions faced for the time of operation.

4. Is there any classes achievable for getting to know wire bonding procedures?

Yes! Numerous companies offer each on-line classes (mainly out there as PDFs) besides functional workshops designed primarily concentrating on engineers seeking deeper understanding about effectual practices inside of a range of contexts like semiconductor packaging or automobile electronics integration options!

5.What are a few usual defects encountered right through cord bond processing?

Common defects embody incomplete bonds due lack acceptable pressure calibration carried out right through setup premier knowledge failures linked vulnerable connections identified through particular visual inspection protocols hooked up for the duration of production lifecycle levels!

6.Are there any inventions these days being researched related to improving current tips & technologies utilized today?

Absolutely! Researchers retain exploring evolved resources along with automatic methods incorporating AI-driven controls aimed optimizing efficiency metrics alongside reducing expenses primary linked average methods employed microelectronics process historically across different sectors cited prior!

Conclusion

Wedge bonding represents a pivotal know-how throughout many sectors—semiconductors being just one illustration—by using delivering professional connections severe for instrument function although navigating towards ever-growing demands referring to density compactness sturdiness envisioned from present day digital designs! As producers hold adapting their strategies alongside evolving consumer expectancies surrounding caliber assurance standards rising traits mean even brighter futures look forward to the ones inclined embrace innovations shaping landscape in advance!