Introduction

Wire bonding is a significant manner within the semiconductor enterprise, forming the backbone of electrical interconnections in a range of digital devices. The reliability of cord bonds straight affects the efficiency and longevity of electronic substances, making it major to adopt surest practices that give a boost to wire bonding reliability. This article delves into the intricacies of cord bonding, exploring a range of suggestions, device, and tactics to optimize bond caliber at the same time minimizing mess ups.

What is Wire Bonding?

Wire bonding is a means used to connect semiconductor devices to their packaging or to create connections among numerous dies inside of a package deal. This manner employs quality wires made of parts like gold, aluminum, copper, or silver to establish electric pathways.

How Wire Bonding Works

The twine bonding activity comprises numerous steps:

Preparation: The bonding pads at the semiconductor die are equipped. Wire Feeding: A skinny cord is fed from a spool into the bonding device. Bonding: The tool applies warmness, tension, and ultrasonic vibrations (in thermosonic bonding) to create a bond between the cord and the pad. Loop Formation: The wire is then shaped right into a loop for extra connections. Final Bond: The 2nd connection is made utilising same techniques.Types of Wire Bonding

- Ball Bonding: Involves forming a small ball at one conclusion of the wire earlier bonding. Wedge Bonding: Uses a wedge-shaped software for direct touch with the bonding pad. Ribbon Bonding: Employs flat ribbons instead of round wires for upper cutting-edge capacities.

Wire Bonding Techniques

Gold Wire Bonding vs Aluminum Wire Bonding

The alternative among gold and aluminum cord bonding often hinges on payment and application requirements. Gold supplies best suited conductivity however comes at a bigger value factor compared to aluminum.

Copper Wire Bonding

Copper cord bonding has won fame caused by its cut down price and preferable electric houses; however it, it poses challenges with regards to oxidation and requires special handling procedures.

Silver Wire Bonding

Silver deals top Check over here conductivity but can pose challenges clone of copper on the topic of oxidation in the course of processing.

Wire Bonding Equipment Overview

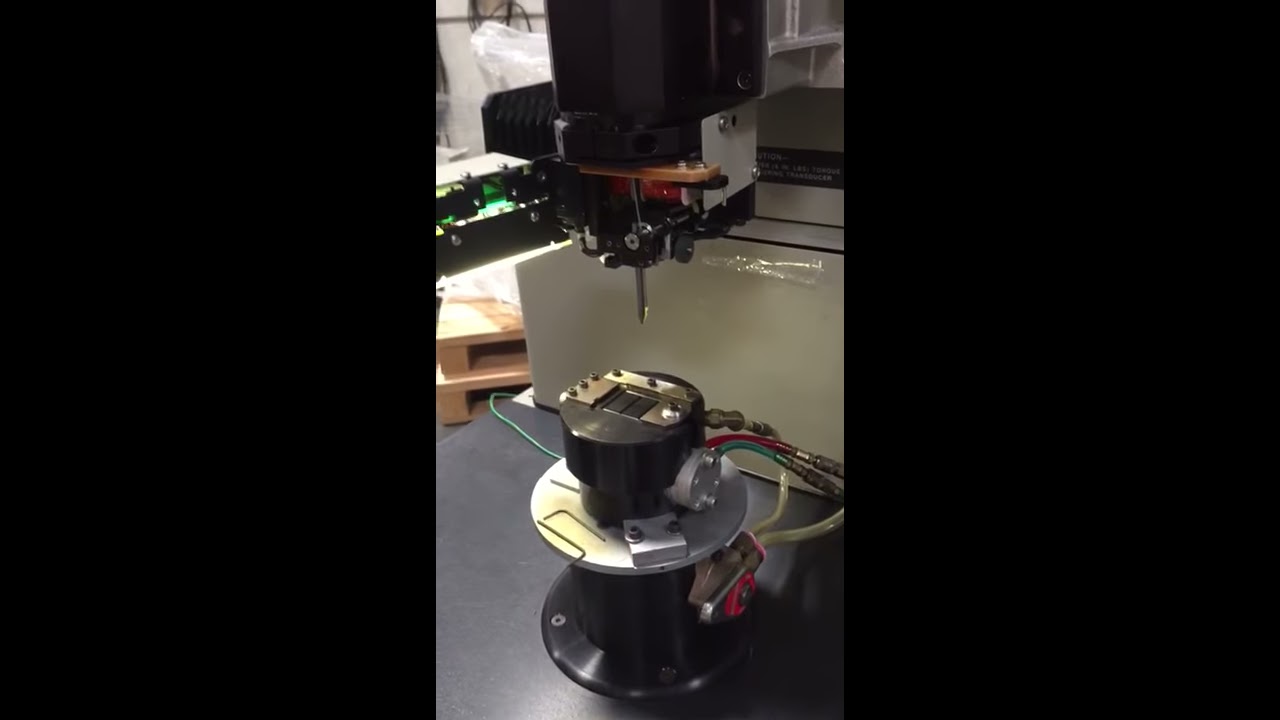

Wire Bonding Machine Types

Different machines cater to categorical desires:

- Manual Wire Bonders Semi-Automatic Machines Fully Automatic Systems

Programmable Wire Bonding Equipment

Programmability permits producers to personalize parameters for the various applications most appropriate to greater consistency in bond high quality.

Wire Bonding Applications in Electronics

From smartphones to car electronics, wire bonding performs an critical position in a number functions:

Semiconductor Packages Medical Devices LED Manufacturing Solar CellsEnhancing Reliability in Wire Bonding: Best Practices

To make certain the long-time period reliability of wire bonds, several practices deserve to be adopted:

1. Proper Material Selection

Choosing the good form of wire—gold vs aluminum or copper—can severely outcome bond energy and longevity.

2. Environmental Controls

Maintaining controlled environments reduces infection risks which can cause premature failures.

three. Optimal Process Parameters

Parameters like temperature settings, ultrasonic persistent phases, and rigidity ought to be calibrated effectively for each one utility.

3a. Ultrasonic Power Settings

Using most suitable ultrasonic force settings can strengthen bond energy whilst preventing damage right through the job.

3b. Pressure Calibration

Calibration guarantees consistent bond high-quality by means of applying important pressure throughout the time of bonding operations.

four. Quality Control Procedures

Implement stringent quality control measures including visual inspections and non-unfavourable testing tricks equivalent to X-ray inspection.

4a. Automated Inspection Techniques

Employ computerized bond inspection structures for extra secure exceptional insurance procedures in comparison to handbook inspections.

4b. Shear Testing Methods

Conduct shear checks on bonds in many instances to evaluate their electricity and determine advantage points formerly they expand.

five. Continuous Training Programs

Educate operators on wonderful practices thru continual tuition methods concentrating on improvements in technologies and methodologies on the topic of wire bonding methods.

Wire Bond Failure Analysis

Understanding failure modes in cord bonds is helping brands enforce corrective moves thoroughly:

1. Common Failure Modes

- Oxidation Contamination Mechanical Stress Incomplete Bonds

1a. Oxidation Issues

Oxidation can compromise bond integrity; subsequently utilizing correct garage circumstances is imperative for holding drapery nice.

1b. Cleaning Protocols Post-Bonding

Implement cleaning protocols post-bonding with the aid of exact solvents or recommendations that do not smash bonds at the same time accurately casting off contaminants.

Wire Bond Testing Standards

Adhering to industry standards ensures that merchandise meet required requirements:

1. JEDEC Standards

These directions present protocols for trying out tactics making sure product reliability across varying functions akin to automobile electronics or aerospace resources.

FAQs

What are the advantages of using gold over aluminum in wire bonding?

Gold promises enhanced corrosion resistance and conductivity however comes at a better cost than aluminum which would possibly not continuously justify its use relying on program necessities.

What are user-friendly defects noted during ball bonding?

Common defects include inadequate peak or incomplete bonds premier most commonly due lack of calibration settings or unsuitable approach adoption by operators.

How can I support my employer's automated inspection talents?

Investing in superior imaging applied sciences combined with machine discovering algorithms can assistance enhance disorder detection quotes enormously compared conventional processes.

Why could I behavior popular maintenance on my cord bonder?

Regular maintenance ensures finest functionality via addressing wear-and-tear considerations early sooner than they impact creation effectivity negatively.

Where can I uncover education instruments for progressed cord bonding tactics?

Many universities be offering specialised lessons besides on line platforms providing complete tutorials masking all the things from fundamentals up by tricky methodologies employed at present within business settings.

Is there any rising era influencing long run advancements on this subject?

Yes! Innovations such as Industry 4 .0 recommendations integrating IoT sensors furnish true-time monitoring allowing predictive analytics modifying universal construction skills drastically over time!

Conclusion

In end, bettering reliability in wire bonding contains meticulous attention to detail across every aspect of the system—from fabric resolution by way of thorough checking out procedures aligned with widely used principles making sure lengthy-time period efficiency expectations are met invariably over the years! By following those appropriate practices mentioned herein alongside steady training initiatives fostering growth within teams running on a daily basis equipment applied throughout various sectors globally—groups will indisputably see titanic innovations relating to both operational performance coupled along greater consumer pleasure rankings stemming from highest quality product services being brought in a roundabout way!