In the sector of electronics production, cord bonding is a quintessential process that connects integrated circuits (ICs) to their substrates or packages. This procedure not solely serves as a important step in semiconductor device fabrication, but it additionally plays a very important function in guaranteeing reliability and overall performance of contraptions. Among a large number of materials used for twine bonding, gold and aluminum are the so much fashionable alternatives. But how do these two materials stack up towards each other? In this text, we are going to delve deep into the Comparing Gold vs Aluminum inside the Wire Bonding Process, exploring their properties, merits, risks, and packages.

Understanding the Wire Bonding Process

What is Wire Bonding?

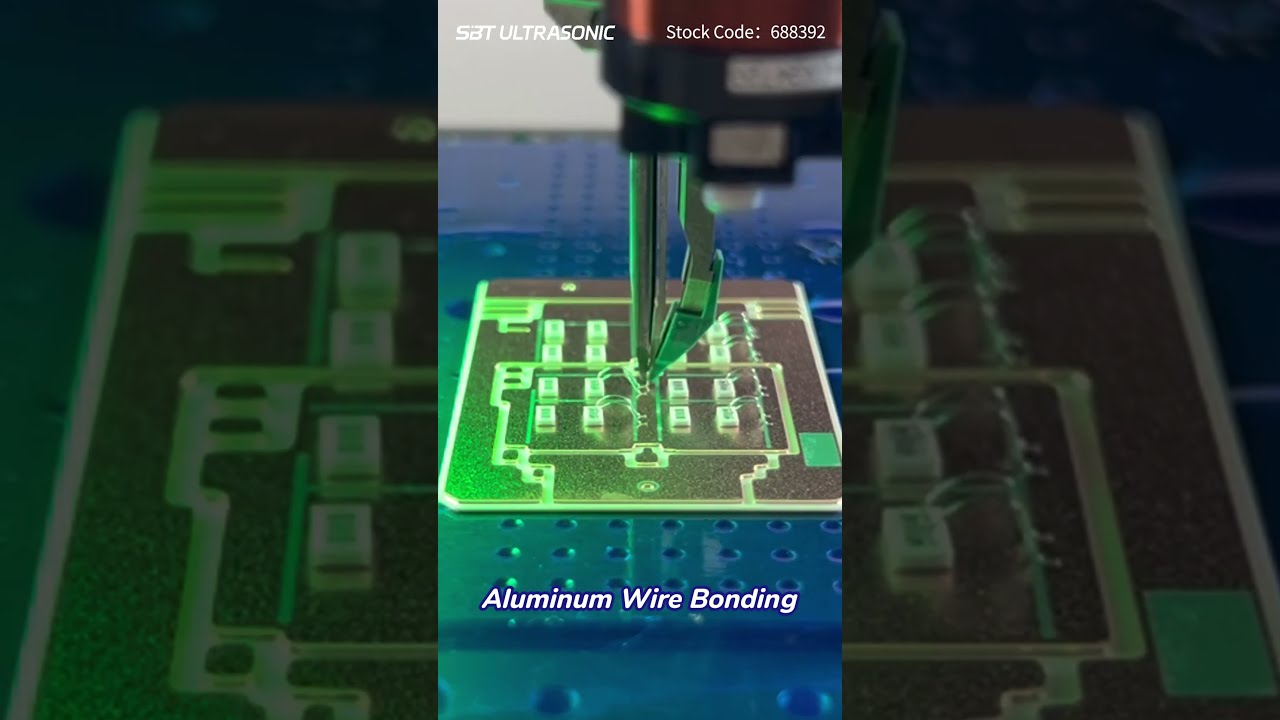

Wire bonding is a technique that involves growing electrical connections between semiconductor chips and their programs or substrates making use of high-quality wires. The wires are traditionally made out of metals corresponding to gold, aluminum, copper, or silver. The method would be executed by various approaches along with ball bonding and wedge bonding.

How Wire Bonding Works

The twine bonding task often includes three major steps: bonding, loop formation, and tail trimming. An ultrasonic or thermosonic vigour resource is ordinarily employed to create robust metallic bonds at extended temperatures.

Types of Wire Bonding Techniques

Ball Bonding: Utilizes a ball-formed conclusion on the wire. Wedge Bonding: Employs a wedge-shaped device for making connections. Ribbon Bonding: Uses flat ribbons in preference to round wires for high-speed programs.Properties of Gold in Wire Bonding

Advantages of Gold Wire Bonding

Gold has routinely been preferred as a consequence of a few qualities:

- Corrosion Resistance: Gold does not oxidize easily, making sure lengthy-term reliability. Excellent Conductivity: It promises awesome electrical conductivity as compared to other metals. Ductility: Gold may be drawn into very skinny wires with no breaking.

Disadvantages of Gold Wire Bonding

However, there are downsides:

- Cost: Gold is drastically more expensive than aluminum or copper. Softness: While ductile, gold may be somewhat cushy, which may possibly end in wear below guaranteed stipulations.

Properties of Aluminum in Wire Bonding

Advantages of Aluminum Wire Bonding

Aluminum has gained popularity for a good number of motives:

- Cost-Effectiveness: Aluminum is noticeably more cost effective than gold. Lightweight: It provides weight savings in functions in which mass is critical. Sufficient Performance: For many applications, aluminum's efficiency is good enough.

Disadvantages of Aluminum Wire Bonding

Nonetheless, it has a few barriers:

- Oxidation Issues: Aluminum conveniently bureaucracy an oxide layer which may impact bond satisfactory if no longer effectively managed. Less Ductility: Compared to gold, aluminum wires are much less ductile and will ruin all over processing.

Comparative Analysis of Gold vs Aluminum inside the Wire Bonding Process

Cost Comparison

When taking into consideration cord bonding check components: | Material | Average Cost consistent with Kg | |----------|---------------------| | Gold | $60 - $70 | | Aluminum | $2 - $three |

As illustrated above, aluminum stands proud as a miles more low-cost preference than gold.

Reliability and Performance

Reliability is paramount in cord bonding purposes:

- Gold Bonds tend to have greater sturdiness via their corrosion resistance. Conversely, while aluminum can practice nicely below controlled circumstances, its susceptibility to oxidation poses disadvantages for lengthy-time period reliability.

Applications in Semiconductors

Both fabrics in finding diversified makes use of within semiconductor technological know-how:

- Gold twine bonding is continuously applied in high-efficiency packages like RF modules and aerospace electronics. Aluminum reveals prefer in automobile electronics by means of value performance.

Wire Bond Quality Control

To ensure that most beneficial performance inside the wire bonding procedure:

Regular inspections with the aid of automatic bond inspection apparatus guide determine matters early on. Various assessments comparable to bond pull tests and shear tests make sure bond capability and integrity.Wire Bond Failure Analysis

Understanding workable failure modes is principal for enhancing reliability:

Bond Lifting: Often effects from poor adhesion at some stage in the initial bonding section. Heel Cracking: Commonly noted with brittle ingredients; it happens while strain concentrates on the bond interface.Implementing rigorous checking out specifications like JEDEC guarantees compliance with marketplace norms.

Conclusion on Comparing Gold vs Aluminum inside the Wire Bonding Process

In abstract, picking among gold and aluminum for wire bonding boils all the way down to application necessities and payment considerations. While gold promises unheard of reliability and conductivity premiere for high-end functions, aluminum affords a practicable substitute for rate-touchy projects without tremendously compromising performance. As technology advances, each resources will keep to play needed roles across a number of sectors — from microelectronics to automobile systems — underscoring their magnitude in revolutionary digital layout.

FAQ Section

1. What are the known modifications among gold and aluminum wire bonding?

Gold affords superior conductivity and corrosion resistance yet at a greater value as compared to aluminum which is more low cost but liable to oxidation subject matters.

2. Can aluminum be used safely in prime-frequency programs?

Yes! While ordinarily less regular than gold for prime-frequency functions via oxidation worries, developments have allowed aluminum's mighty use below particular situations.

three. Is it conceivable to change from gold to aluminum twine without compromising reliability?

Switching components deserve to involve thorough trying out on account that exceptional thermal enlargement premiums may possibly have an effect on bond integrity through the years.

four. How do environmental causes influence twine bond excellent?

Humidity and temperature can particularly affect oxidation charges and for this reason have an impact on normal bond good quality; for this reason environmental controls are obligatory throughout creation methods.

5. Are there any choices to gold and aluminum in wire bonding?

Yes! Copper and silver also are used; despite the fact that they arrive with their wire bonders possess set of challenges similar to oxidation (for copper) or expenditures (for silver).

6. What function does working towards play in efficient wire bonding methods?

Proper training ensures that operators take note nuances associated with textile managing such as laptop settings which in some way results in elevated yield quotes at some stage in production cycles.

By contemplating all sides highlighted above – from expenditures associated with both subject material model by using workable failure research – brands can make knowledgeable offerings that align with their operational desires at the same time as maximizing product efficacy inside competitive markets!